Platform Leader: Wenping Yin

Deputy Platform Leader: Genevieve Dennison (DST)

Researchers

Industry Collaboration

Exciton Science Research Groups

The risk of terror attacks has prompted scientists to invest time and effort in developing smart materials to detect chemical and biological warfare agents. The field of sensors for these materials is extremely broad, encompassing very simple paper-based test strips for liquid chemicals right through, to large high-tech instruments for detecting biological agents.

In partnership with the Defence Science and Technology Group (DST), the Centre is in a unique position to develop portable and robust chemical sensors with high sensitivity and specificity. DST is investigating technologies that can be included in such a device, with particular focus on a photoluminescence-based response system.

The goal of this platform is to develop emerging emissive materials, robust strategies and analysis procedures for miniaturising and simplifying luminescence chemical sensors with lower economic cost than existing large laboratory instruments, higher sensitivity than ordinary paper tests and better selectivity than electrochemical detectors.

The development of a novel fluorescence-based chemical sensor will need developments around chemical probes, substrate materials and simulation to understand the chemical interactions with specific gases and how to best optimise the structural properties in a material to deliver the necessary speed, sensitivity and selectivity.

After building the basic characterisation equipment and control facilities, finishing the testing experiments in the first two years, in 2020, the platform has worked on upgrading facilities, developing new sensor materials, understanding the sensing mechanism and expanding the sensor applications to broaden analytes. To fulfil the platform objectives, these factors were designed as four work packages:

| Name | Node |

|---|---|

| Wallace Wong | UoM |

| Paul Mulvaney | UoM |

| Jacek Jasieniak | Monash |

| Name | Organisation |

|---|---|

| Rebecca McCallum | DST |

| Genevieve Dennison | DST |

| Name | Node |

|---|---|

| Wenping Yin | Monash |

| Nicholas Kirkwood | UoM |

| Name | Node | Student type |

|---|---|---|

| Ben Tadgell | UoM | PhD |

| Hanchen Li | Monash | PhD |

| Na Wu | UoM | PhD |

| Tze Cin Owyong | UoM | PhD |

| Jacob Fry | UoM | PhD |

In 2020, the platform continued to work on developing new fluorescent materials as sensor probes. The probe testing equipment at the University of Melbourne and at Monash University are operational and upgraded. The nanocrystal caesium lead halide perovskite materials developed in CI Jasieniak’s group are looking extremely promising as halide sensors. A patent application has been filed in that space, one peer-reviewed article has been published, and two more papers are in progress. Another collaborative project between the groups of CIs Mulvaney and Wong has developed a quantum dot (QD) downshifting coating for LEDs. The blue QD film has shown great potential as the energy sources of the sensing devices, the next step will be to address the tuneability of the wavelength and integration with the LED device. The sulfur mustard project has been performed using the mimic chemical, CEES, with a comparable sensitivity of the current methods. Real sulphur mustard detection experiments have been carried out at DST with strict safety controls. As an important milestone, the detection of sulphur mustard performed highly as expected. The next stage of this project will be to apply the sensor system to extend into another chemical warfare agent, nitrogen mustard.

In partnership with DST, we have started to work on a new compact sensor capable for aerosol detection. We are improving the sensitivity aspect of that device with another project planned to broaden the device applicability. A new PhD student Jacob Fry joined this project in early 2020.

Spectrum characterisation equipment and control facilities of the analytes has been established and we have been using these facilities to characterise and test our novel chemical probes. We can obtain time-dependent spectroscopic data over the entire ultra-violet to visible to near-infrared range (up to 1700 nm) over a wide temperature range (-30 to 110 °C) appropriate for chemical sensing. We can also handle gaseous analytes and perform detection experiments on solid substrates.

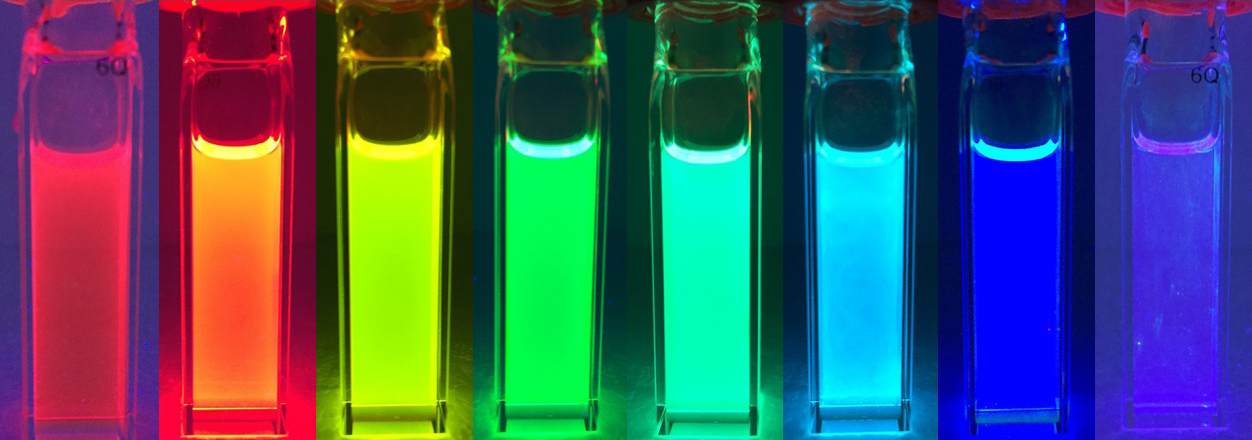

Several fluorescent organic probes were synthesised and tested against two analytes – methyl bromide and mustard gas. While some organic probes showed detection of these analytes in solution, their sensitivity and stability were limiting factors. The platform has also been developing caesium lead halide perovskite nanocrystals as fluorescent probes. These perovskite nanocrystals showed rapid (time response in seconds) and sensitive (limit of detection at 30 parts per billion by volume) response to halide compounds. This combination of speed and sensitivity makes these perovskite nanocrystals benchmark materials for detection of halide compounds on solution. Detailed studies were completed on the detection of methyl iodide and methyl bromide by the perovskite nanocrystals and testing is in progress for the detection of sulfur mustard and its simulants. Lastly, the platform has developed multi-stimuli responsive fluorescent probes targeting proteins. While the probes are designed to study biological processes, we envisage that they can be used in chemical and biological analyte sensing.

To achieve chemical sensing of gases on solid surfaces, microporous polymer substrates were coupled with the perovskite probes. We have identified issues with probe-analyte interactions at the gas-solid interface and will examine alternative approaches in 2021. We have completed theoretical and experimental studies on the mechanism of halide compound sensing by perovskite nanocrystals.

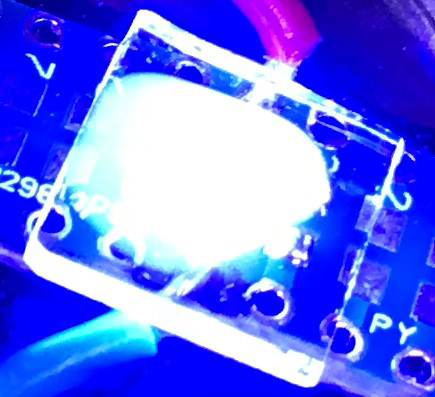

One of the chemical sensing device designs requires the use of a compact light source to excite the fluorescent probes and analytes within the device. Ideally, the compact light source has high intensity, narrow spectral width, and low power consumption. We are developing a fluorescent coating to improve the light source performance which will ultimately result in enhanced sensor performance. Apart from device integration, we have completed the investigation in the use of blue quantum dot/polymer films to achieve narrowing of spectral width. We are also exploring the perovskite materials in polymer films.

Apart from studying microporous polymer substrates in 2020, we started a new project exploring a different sensor device design to enable better gas/liquid/solid interactions. The new device design allows the capture and detection of analytes in a filter. It is anticipated that much of the sensor work will be focused on this new device configuration in 2021.

As in any measuring system, the analyte determination requires, in addition to the measurement of the luminescent response, a calibration of the sensor. Calibration is one of the current challenges in photoluminescence sensors, because of the costs associated to calibration, or the deviation of the calibration curves from theoretical models for particular immobilising matrices, for extreme ranges of the analyte concentration, or because of interfering processes. Our perovskite nanocrystal probe has great potential in this respect as the spectral shift on detection of analytes showed high consistency.

Colloidal solutions of inorganic perovskite nanocrystals which have been used as chemical sensing materials shown under UV light.

Zinc sulfide quantum dot/polymer film downshifting UV light from LED to blue light.

DST has been involved in this platform since its inception and has provided information and guidance on the state-of-the-art application aspects of the platform. DST has been developing prototype chemical sensing devices. The main goal of the Centre is to develop chemical probes that can be used to improve these prototype devices. To this end, there has been continuous exchange of information and discussions between DST and the Centre to ensure appropriate focus on the problems that DST wants to solve. Dr Genevieve Dennison, a Defence Scientist and Chemistry Specialist at DST, has been added to the Centre as a PI. She is the primary contact point between DST and the Centre.

| Name | Organisation | Project Responsibility |

|---|---|---|

| Genevieve Dennison | DST | Provide input on sensor development and device integration. |

| Rebecca McCallum | DST | Provide input on sensor development and device integration. |

| Gregory Barbante | DST |

Incorporate QDs as downconverters into the LED light source used in the MIST sensor. Provide input on the aerosol detection. |

| Nicholas Fitzgerald | DST |

Incorporate QDs as downconverters into the LED light source used in the MIST sensor. Provide input on the aerosol detection. |

There have been some changes in personnel in this platform. A new PhD student Jacob Fry has been recruited to focus on the sensor device project addressing some of the personnel shortage issues. With the success of the perovskite sensor project, PDRA Wenping was promoted to platform leader in 2020. With small personnel commitment in this platform, we have been successful in running two small-scale collaborative projects - CsPbX3 perovskites as sensor materials and quantum dot downshifting films. With several PhD students concluding their studies this year, it will be important to recruit more people to work in this platform for the next 3 years. As with many aspects of the Centre, COVID-19 disruptions is having a negative impact on recruitment of personnel.

The work in Platform 3.1 to-date has resulted in the discovery of a class of nanocrystal sensor materials, the establishment spectroscopic facilities for materials characterisation and testing and insights into the difficulties in integrating sensor materials into devices. The first-generation sensor device design draws gases and aerosols from the surrounding environment and flows them over substrates containing the sensor material. We discovered that the limiting factors of this device design are the reliance of adsorption and trapping of analyte species on the substrate in a very short timeframe and the rapid reaction required between the analyte and sensor material essentially in solid state. As most chemical reactions occur much more readily in solution, we aim to work with a sensor device design that allows solution chemistry but remain portable and robust. Objectives include:

PhD student, Jacob Fry, is laying the foundations for this platform direction. We will be recruiting new personnel to support this effort. The work on perovskite sensors materials and quantum dot downshifting films will have concluding milestones in 2021 and we will be planning and starting the next phase of those projects.